Getting Ready to Drill at WAIS

Ice Cores from last year are being moved quickly to a Hercules C130

"cold

deck" flight. Last year we drilled though the zone known as

"brittle ice",

which needs to adjust to surface pressures for nearly a

year before

transporting. This year's cores are being flown out

this year since they are

part of the "brittle ice" zone and not as fragile.

Believe it or not, this room where the ice cores are handled is

refrigerated

to -20 C to keep the ice cores closer to the temperatures they see in

the

bore

hole. This room is insulated from the "warmer"

outside air, and fog hangs

in the air and frost coats everything as cores are moved to the plane.

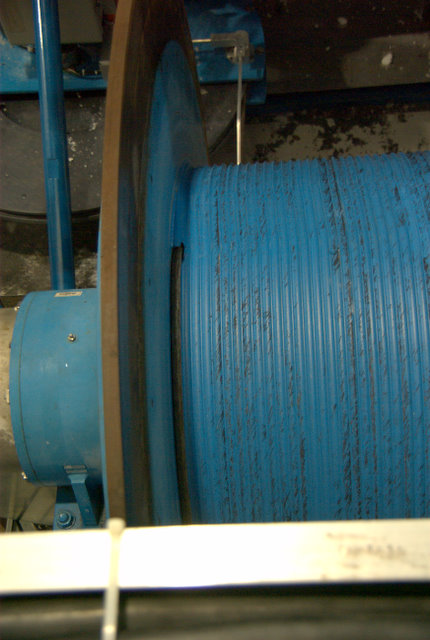

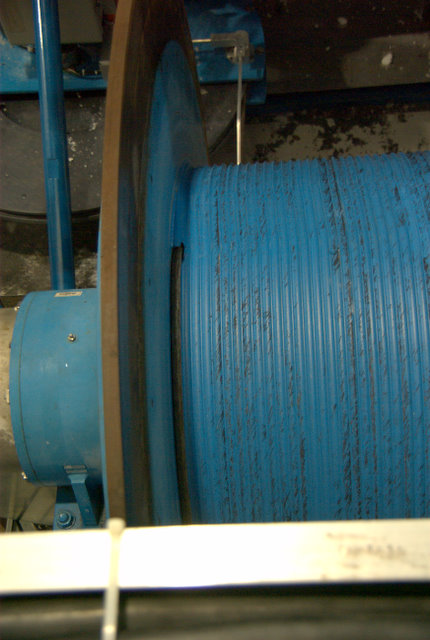

A new 4 kilometer long cable needs to be installed on the winch this

year.

The old cable is too short, and was used for the first 2

seasons of drilling as

an "expendable cable" with the shorter depths of the early

seasons. This

cable is about 1/2" in diameter, and has two steel outer layers, 2

electrical

copper layers, and 7 inner optical fibers. Six of the

fibers are used to

communicate with the Sonde's (drill) two internal computers, the

seventh is

a spare. The copper layers run up to 1000 VDC at 10 Amps to power

the Sonde.

The steel layers handle up to 40,000 Newtons of force

to lift the Sonde and

with the ice core to the surface.

The very end of the cable as it is wrapped onto the winch drum.

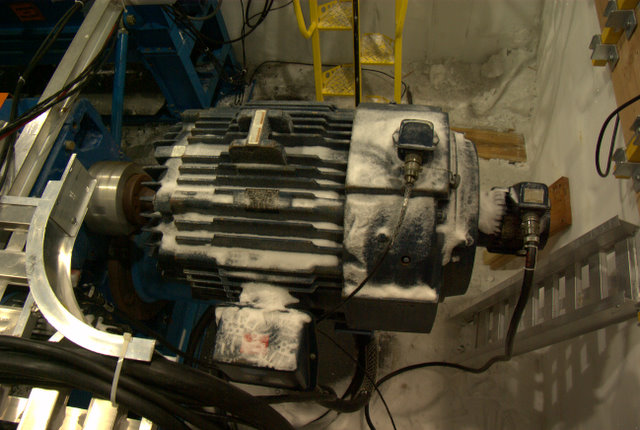

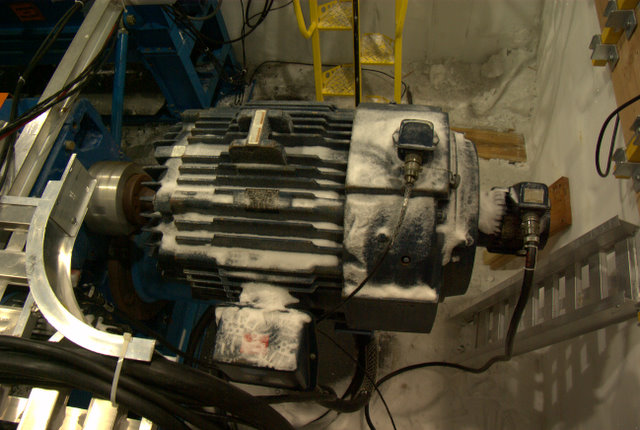

This 150 horse power motor is the "Trip" motor that powers the winch

drum.

The trip motor is used raise and lower the Sonde in the bore hole in a

relatively

quick speed when precise control is not needed. Not pictured is

the 3 horse

power "drilling" motor which controls the drum when fine control is

needed

during the actual ice core drilling.

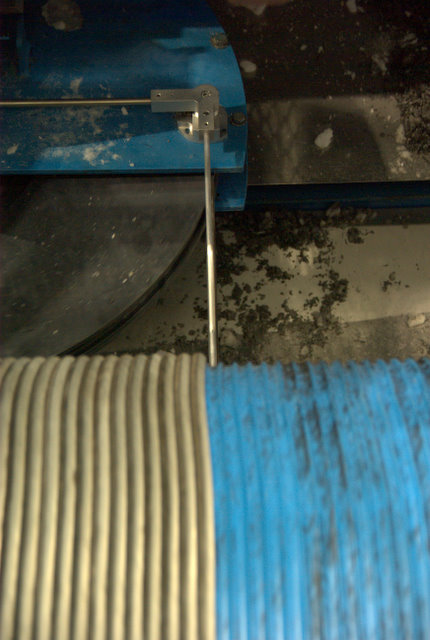

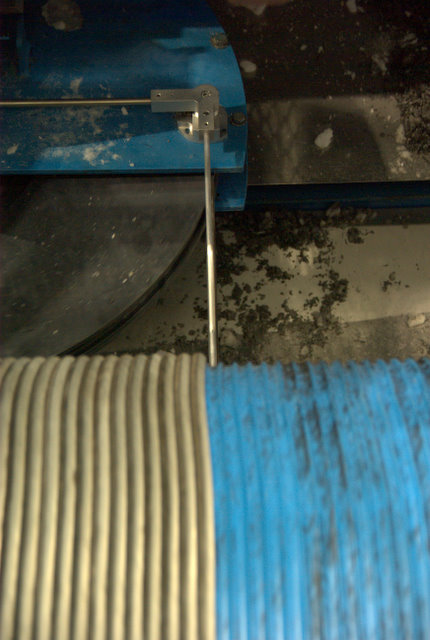

The first layer of the cable is winding smoothly on to the winch drum.

To the right is the 150 hp trip motor. The "level wind" is the

pulley that

moves left or right to guide the cable neatly on to the drum. On

top of the

blue guard for the pulley, is the attendant sensor/feedback arm

mechanism

that speeds up or down the lateral movement of the level wind pulley.

Patrick and Lou are in the slot, adjusting the drip pans. The

slow movement

of the ice is warping all the walls and floors in the slot and the rest

of the arch,

so the drip pans which guide the drilling fluid back into the bore hole

needed

adjustment before drilling could begin this year. A white

Styrofoam plug is jammed

in the bore hole casing to prevent a the disastrous that would be

caused by the

simple drop of a tool into the bore hole. Safety harnesses, with

a fall

preventing cable, are being used when climbing into and out of

the slot.

The new cable fully on the winch drum, Elizabeth cleans the level wind.

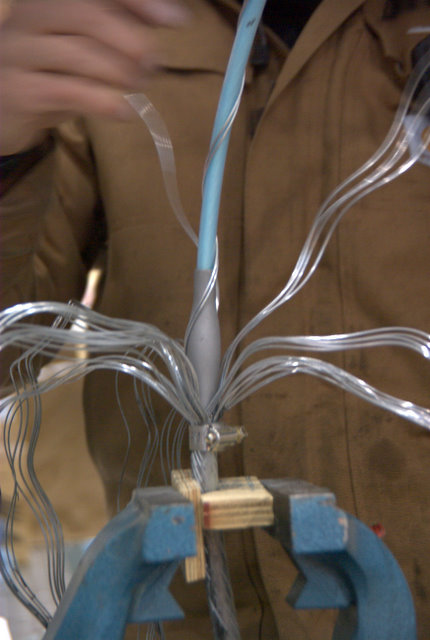

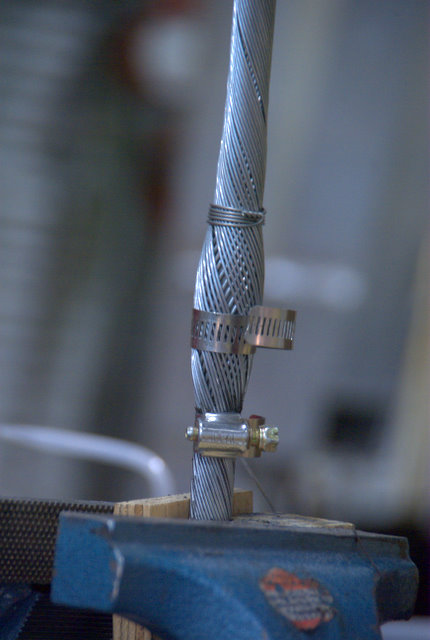

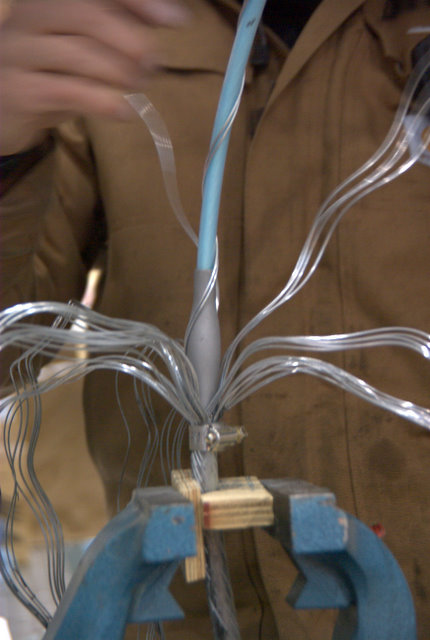

Cable termination in progress!

Jay is expertly unwinding the steel wires which from the outer two

layers

of the new cable.

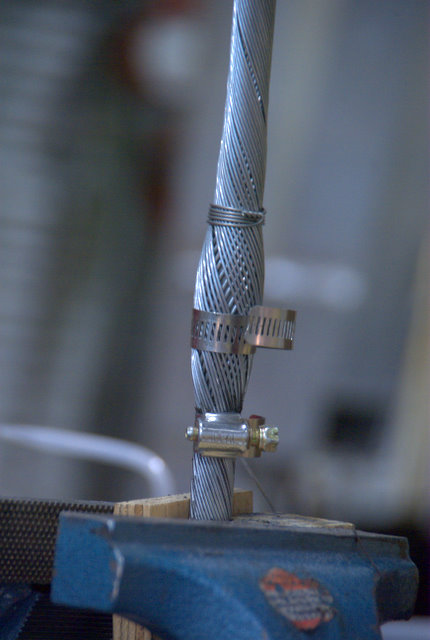

The steel wires are carefully rewound on to a mandrill which will hold

all the pulling force required to break off an ice core and return the

Sonde

to the surface.

Here the rewinding of the outer steel layers of the cable is complete.

Neat work Jay, as usual.

Krissy and Jay have stripped the two electrical copper layers to the

required

specifications, and they get to work reaching the delicate optical

fibers near

the center of the cable. The optical fibers are the most exacting

portion of

cable termination, the ends of each fiber requiring optical polishing

to the

sub-micron level.

Krissy and Nicolai are attaching the cable to the upper portion of the

Sonde,

called the "anti-torque" section. An anti-torque spring is

visible in the lower

right. The springs cut into the bore hole sides to prevent the

whole drill from

counter-spinning when the lower portion of the drill is spinning to cut

the ice core.

In the center of the anti-torque section, you can see brightly colored

"armored" jackets which cover the fragile fiber optic cables.

Nicolai is wiring

the high voltage copper layers to the Sonde's internal power input

cables.

Nicolai finishes cable termination as Patrick holds a heater to keep

Nicolai's

fingers warm -- sort of.

And fingers do get cold at 5 F in the Arch! The artwork is from a

previous year's drilling team.

This year's drill modifications mean it is longer than last year.

The flooring at the far end of the slot needed to be moved back.

A view of the Arch.

The Arch is the only "permanent" building at WAIS. As such, it is

buried by snow drifts to the full height of the Arch. Here's the

view

from the personnel entrance door. About 25 feet to the surface!

The drill end of the Arch from the outside. WAIS "town" is to the

right (not

visible due to the terrain. The power lines reach to the two

generator buildings,

the top of those building's exhaust vents are on the right.

The view to the Arch to left of the last picture. Nothing.

Nothing

but snow

and sky.

John, Tommy, and Ryan and Heidi prepare ice cores for shipment.

John and Ryan bagging ice cores.